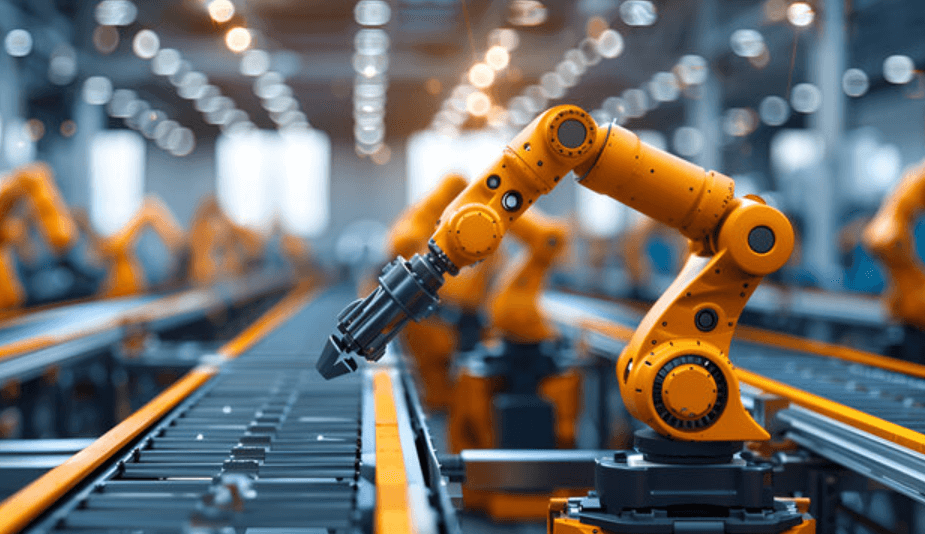

The Role of Robotics in Modern Manufacturing Processes

Robotics has transformed modern manufacturing by enhancing efficiency and precision in production processes. Automated systems reduce labor costs and minimize waste, leading to consistent quality and increased output. However, the integration of these technologies introduces challenges that organizations must navigate. Additionally, the evolving landscape of workforce dynamics necessitates a reevaluation of skill requirements. Understanding these complexities is vital for companies aiming to leverage the full potential of robotics in their operations. What implications does this have for the future?

Benefits of Integrating Robotics in Manufacturing

As organizations strive for operational excellence, the integration of robotics in manufacturing offers significant advantages that enhance productivity and efficiency.

Robotics facilitates cost efficiency by minimizing labor costs and reducing waste through precision.

Additionally, automation leads to productivity enhancement by increasing production rates and ensuring consistent quality.

These factors collectively contribute to a competitive edge in the rapidly evolving manufacturing landscape.

See also: The Role of Quantum Computing in Modern Tech Innovations

Challenges in Implementing Robotic Systems

Despite the numerous benefits associated with integrating robotics in manufacturing, organizations face several challenges during implementation.

Cost considerations often hinder investment, as initial outlays for robotic systems can be substantial.

Additionally, technical limitations in existing infrastructure may restrict seamless integration, requiring further investments in upgrades or modifications.

These factors necessitate careful planning and evaluation to ensure successful deployment and optimization of robotic technologies in manufacturing environments.

The Impact of Robotics on Workforce Dynamics

While the integration of robotics in manufacturing offers significant efficiency gains, it also triggers profound changes in workforce dynamics.

Job displacement emerges as a critical concern, necessitating a shift in workforce skill sets. Workers must engage in skill adaptation to remain relevant, transitioning from routine tasks to roles that emphasize problem-solving and oversight, thereby redefining the nature of employment in a rapidly evolving industrial landscape.

Future Trends in Robotic Manufacturing Technology

Emerging advancements in robotic manufacturing technology are poised to reshape the industry landscape significantly.

Collaborative robots are increasingly integrated into workflows, enhancing human-robot interaction and safety.

Meanwhile, autonomous systems are advancing towards greater decision-making capabilities, optimizing production efficiency.

These trends indicate a shift towards more flexible, adaptive manufacturing environments, ultimately empowering organizations to leverage automation while maintaining operational autonomy and workforce engagement.

Conclusion

In conclusion, the compelling convergence of robotics and manufacturing heralds a new era of enhanced efficiency and effectiveness. While challenges persist, the potential for productivity and precision propels progress. As industries embrace emerging technologies, the symbiotic relationship between machines and human operatives will foster a future filled with innovation and improvement. Ultimately, the success of modern manufacturing hinges on the harmonious integration of robotic systems, underscoring the necessity for skillful adaptation and continuous advancement.